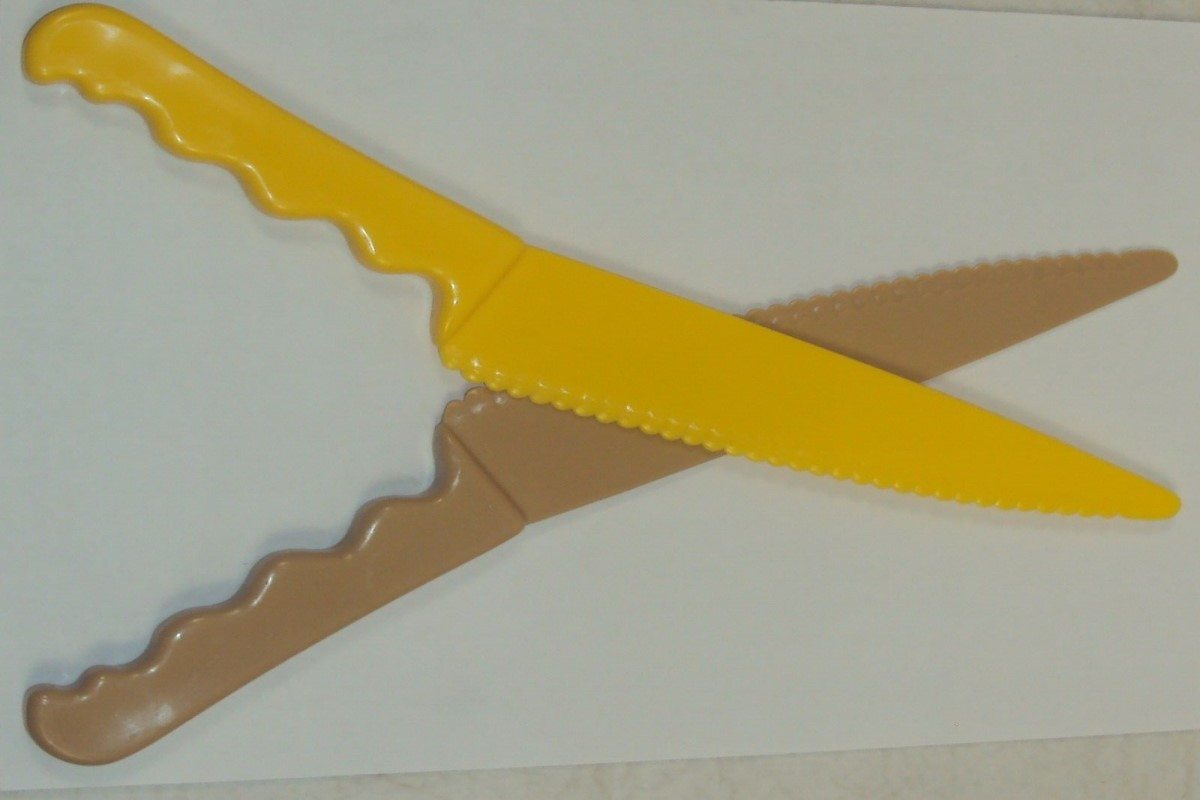

If you want to cut your fruit and other vegetables easily our serrated knife made of plastic will help you.

When you have the correct equipment, preparing meals is quicker, faster, and safer. However, because there are so many various types of knives available on the market, it can be challenging to pick the one that best meets your requirements.

It is all too easy to buy a collection of specialized knives you hardly ever use if you do not have the appropriate information. As a result, you may find yourself having a selection of unused knives languishing at the back of your kitchen equipment drawer.

The various components that make up a knife; the dissection of a chef’s knife

If you want to select the knife that is of the highest quality for a specific job, it will be helpful to have a fundamental working understanding of the various components that make up a knife. In this section, we will describe the many components of a knife, including their names and the purposes they fulfill.

It is important to keep in mind that the preceding is merely a summary of the various characteristics that are common to the majority of standard knives; the construction of several specialized knives may vary slightly.

The exact tip of the blade. Also called the point. You can puncture or score the surface of food with this, as it is typically sharpened to a fine point.

The section of the knife that actually does the cutting is called the blade, and it is referred to by that name. Steel is the most common material used in its construction; however, it could also be made of ceramic, titanium, or even plastic.

The term “edge” refers to the part of the blade that has been sharpened and is utilized to perform the majority of the cutting work.

The degree to which the edge is ground determines the sharpness of the knife, and this, in turn, is determined by the overall quality of the knife as well as the frequency with which it is sharpened.

Either it has serrations, like those found on bread knives, or it is completely straight.

The area of the knife’s edge that is closest to the point and immediately in front of it is referred to as the tip. It is the portion of the blade that is typically put to use while performing more precise chopping and cutting tasks.

The side of the blade that faces away from the cutting edge and is duller than the other two is called the spine. The thickness of the blade’s spine is directly proportional to the blade’s overall strength; as a general rule, the thicker the spine, the stronger the blade.

Additionally, it is essential for maintaining the overall knife’s sense of equilibrium.

The part of the blade that is the furthest away from the tip and is located close to the bolster is called the heel. It’s typically the section of the blade that’s the widest.

When the chef requires more strength or pressure to cut through meals that are thicker or tougher, they typically use this area of the edge because it is the most accessible.

The section of the blade that is not sharpened and that connects the handle to the cutting edge of the blade is called the tang. The tang plays an essential role in determining the knife’s overall balance, weight, stability, and strength.

Many people believe that the best knives are those that have what is known as a “full-tang,” which is a tang that extends all the way from the tip of the blade to the handle. In some configurations, the tang doubles up as a handle for the tool.

Handle or scales: The part of the knife that the chef grips while using it is termed the handle, although it is also sometimes referred to as the scales.

It can be constructed out of a variety of materials, and its shape can either be straight or curved, with finger grooves and other ergonomic elements that make it simpler to grasp.

Some knife producers omit the handle entirely and fashion the blade and tang of the tool out of a single piece of steel. This configuration allows the tang to double as the handle of the tool.

The edge of the blade is what determines how sharp it is, making it unquestionably the most crucial component of any knife.

As a result of the fact that different sorts of edges are required to cut through various meals, we are going to run through the many types of edges and explain which tasks are best suited to each type.

The edge that is straight

A flat ground edge or straight edge is another name for the most common type of edge, which is also known as a straight edge. It is most commonly seen on utility knives, paring knives, and chef’s knives.

Edge with serrations

A blade with a serrated edge is one that has sharpened grooves and ridges running the entire length of the blade. This type of edge is useful for cutting through harder foods.

They are also handy for slicing softer foods without smashing them out of shape, which is something that can be difficult to accomplish. Knives designed specifically for cutting bread, tomatoes, and steaks typically have serrated edges.

a border with scallops

A scalloped edge is characterized by the presence of hollow dimples down the side of the blade. These dimples prevent food from adhering to the surface of the knife.

A Granton edge knife is another name for one of these knives; the name comes from the company that was the first to patent the design. When cutting through moist or sticky materials, such as raw fish or vegetables, they come in especially handy.

This style of blade is frequently found on Japanese santoku knives as well as salmon knives.

Edge with a hollow grounding

A hollow ground edge is a type of edge that tapers down from the middle of the blade to create an extremely fine and sharp edge. This type of edge is typically found on Japanese knives.

They will be exceptionally sharp as a result of this, but they will also be more prone to wear and fracture, and they may require sharpening more regularly. The cutting edge of a nakiri knife will nearly always be hollow ground.